ibg offers a wide range of coils to assist in eddy current inspections. Depending on your needs and what you are testing, you may require several different types or sizes of coils with varying frequency ranges and sensitivities. All ibg coils work with all ibg eddy current structure testers, so you will ensure that your investment in an ibg eddy current system will last for years to come.

Need assistance in selecting which ibg coils you need for your particular eddy current application? Contact a Berg sales engineer by calling 847-577-3980 or email to info@bergeng.com.

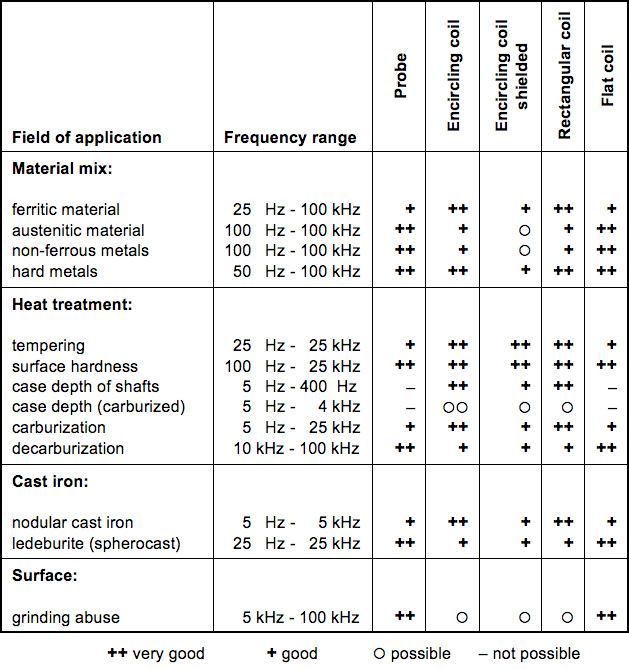

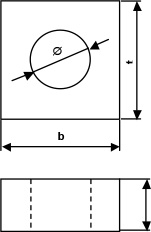

Ensuring the Right Coil for Each Eddy Current Inspectionibg offers a wide range of accessories for structure testing including encircling coils, rectangular coils, inner diameter coils, flat coils and probes. Their coils possess the highest test sensitivity levels and temperature stability of any eddy current solution currently offered. If you require a customized solution, please contact Berg Engineering and we will work with you to find a solution that will meet your inspection requirements.Standard & Customized Coils for All ApplicationsEncircling CoilsWhen testing for correct heat treatment with the Preventive Multi-Frequency Technology by ibg, we recommend using encircling coils. They come in standardized diameters from 5 mm up to 300 mm (larger coils are available upon request). 90%+ of all applications will work with coils in those sizes within that range. Specific testing applications might include checking for the correct hardness, case depth, material mix, alloy, or crystalline structure, in addition to many others. Some applications will require special coils and sensors designed for a specific test task. ibg has a department specifically created to address exceptions and can manufacture coils to meet each application you may have. As an example, it can make sense to use rectangular coils when testing bearing rings so you can test the material with a magnetic field. Similarly, testing of con-rods is an application that can use rectangular coils. However, when differences in positioning of the hardening zone need to be detected, as in the induction hardening process, special shielded coils can be manufactured for you. In this case, the magnetic field is shielded so that only the critical area is tested (eliminating ambient influences). Very small deviations in position of only 0.5 mm can be reliably detected for most parts and geometries.Testing Boreholes & Inner Diameters with ID CoilsInner diameter or boreholes are often not measurable by standard encircling coils. Specifically, the magnetic field of these coils cannot usually penetrate the material from outside to allow for a reliable test. Typical examples include races in a hub or the inside of bells of a constant velocity joint (CV-joint / tripod). ibg developed ID coils to test such parts with appropriate sensitivity and reliability. The ID coils are tailored just for this application, allowing areas inside the test part to be reached and tested correctly. The photos here show test coils for constant velocity joints. ibg makes ID coils starting in 5mm diameter range. ibg can also manufacture ID coils in stainless steel to guarantee a long useful life for applications with a high number of parts and short cycle times.Customized Coils for Testing Small PartsIf small components fail, they can lead to an entire component breaking down. If small parts' heat treatment is incorrect or non-treated and they become part of a larger component, e.g. injection pumps or steering, this may cause malfunction of the entire part. These types of failures can be prevented with a 100% test of such components for correct heat treatment. ibg specializes in testing small components and can offer customized solutions for testing these parts. Encircling coils can typically test for these parts in round or rectangular configurations. ibg designed its Preventive Multi-Frequency Technology for these applications and included its Simultaneous Harmonic Analysis in all of its structure test instruments to solve these problems. |

Structure test on screws shown with a typical application for circular coils.

ibg coil testing the internal diameter of a cut test part. Demonstrates the shifted hardness profile.

Specialized ibg coils used for testing very small components.

ibg special coils and their test parts (from back to front): rectangular coil, ID coil, shielded circular coil |

|

Size | Dimensions b x t x h (mm) | Inner Diameter (mm) |

| 1 | 80 x 80 x 35 | 10, 16, 25, 40 | |

| 2 | 150 x 150 x 50 | 50, 63, 80, 100, 125 | |

| 3 | 250 x 250 x 50 | 160, 180, 200 | |

| 4 | 380 x 380 x 50 | 250, 300 |

Other inner diameters can be made to specification.

Available frequency ranges include: 25 HZ - 25 kHZ (standard) / 5 Hz - 5 kHZ / 100 Hz - 100 kHz

|

Diameter d (mm) | Length l (mm) | Frequency Range |

| 10 | 46 | 2.5 kHz - 250 kHz | |

| 16 | 47 | 250 Hz - 25 kHz | |

| 25 | 51 | 25 Hz - 2.5 kHz |