Learn what an NDT-approved carrier is, and what sets it apart from commonly used, non-approved base oils such as Isopar M or kerosene.

What is an NDT carrier fluid?

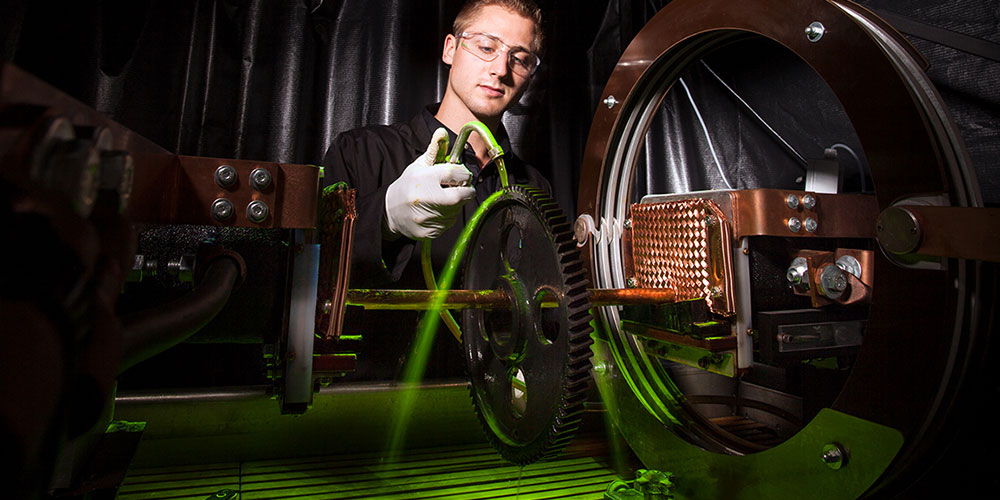

An NDT carrier fluid is the fluid in which fluorescent and nonfluorescent magnetic particles are suspended to facilitate their application.

Also known as a petroleum-base suspension vehicle.

What makes an oil carrier categorized as NDT material?

- An NDT-approved carrier is a light petroleum distillate that imparts magnetic particle suspension stability and mobility.

- It is virtually non-fluorescent so it will not interfere with the detectability of fluorescent magnetic particle indications.

- NDT-approved carrier oil prevents corrosion of most alloy parts, and prevents corrosion of equipment components in magnetic particle testing machines.

- Viscosity promotes good magnetic particle movement. Per ASTM E709 Standard Guide for Magnetic Particle Testing, the viscosity of an NDT-approved carrier vehicle should not be higher than 3.0 cSt at 100°F / 38°C and not more than 5.0 cSt at the lowest temperature the carrier is used at.

What makes an NDT carrier fluid different from a non-NDT petroleum-base oil like kerosene or Isopar M?

A NDT Carrier fluid is:

- Very low odor: for operator safety and comfort

- Nonfluorescent: so oil does not produce excessive fluorescent background that will interfere with fluorescent indications formed by fluorescent particles

- High flash point: for safety

- Low viscosity: less than 5 centistokes for proper particle mobility and indication formation

What is the safe zone a carrier’s flash point should be within?

NDT carrier fluid should have a flash point above 200°F / 93.3°C. This high flash point is safe for use in most facilities, while promoting a safe work environment for NDT operators.

Why is it important to have a high flash point?

A high flash point improves operator and plant safety, and helps prevent fires. OSHA typically requires a flash point at or above 200°F / 93.3°C for fluids that are used in open tanks.

What are the dangers of using an oil with a lower flash point?

- Fire

- Damage to the mag particle testing equipment

- Injury to operators

- Down time

- Costly repairs and replacement

What are dangers of not using an NDT-approved carrier?

- Less inspection reliability: Fluorescent carrier oil may interfere with inspection

- Poor particle mobility: Viscous (above 3.0 cSt at 100°F / 38°C) carrier oil will impede particle mobility and formation of indications

- Clumping of magnetic particles: NDT carrier fluid offers good magnetic particle suspension stability and good particle mobility which enhances indication detection

- Corrosion of your magnetic particle unit: Using a NDT carrier fluid will protect equipment components on the mag particle unit from corrosion, leading to less maintenance and repair of the mag particle equipment and lower maintenance and repair costs. MPI units that use NDT carrier fluid look virtually new even after several years of use

- Higher background fluorescence: Difficult inspection (fluorescent indications formed by fluorescent magnetic particles will not jump out against strong fluorescent background)

- Low flash point: Low flash point oils are unsafe. Fires can happen when using low flash point oils. Low flash point oils are not safe for the NDT operators.

- Poor working conditions for operators: Strong odors, flammable oils (fire, safety), difficult inspection due to excessive fluorescent background caused by fluorescent oil

We’ve republished this article from our friends at Magnaflux that we thought our readers would like! Thanks to Cheri Stockhausen, Product Applications Manager at Magnaflux.